Having developed strictly PC software for 10 years, it was time to look into something new and fun. My erlier interest in electronics was awakened in 2006/2007. Target applications is no longer analogue audio electronics but microcontroller based embedded systems. Significant things had happened since I last worked with electronics so I had some catching up to do. My first goal was to build my own tools for producing double-sided prototype cirquit boards with surface mounted components. I reached this goal in November 2007. I learnt alot about cirquit board design and manufacturing while building these tools, and that was the idea.

Double-sided UV-lightbox

First tool was a UV-lightbox for exposing cirquit boards. The timer is based on a microcontroller which uses optotriacs for controlling the UV-tubes. Vacuum from a refrigerator compressor is used to hold the cirquit board and mask in place during exposure. 4 minute exposure gives perfect result when using overhead film and laser printer for making the mask.

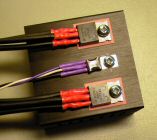

General purpose temperature regulator

For reflow soldering surface mounted components, a very special and accurate temperature regulator is needed. So I made a general purpose microcontroller based regulator with special programs for reflow soldering. The regulator has two 230 VAC outputs for the heating elements and one 12 VDC output for cooling fan or similar. It supports two high-temperature K-type sensors and two lower temperature sensors of type DS18x20 or SMT160-30, and has a USB port for logging data to a PC. The software in the regulator is multitasking so that several programs can be running simultaneously, as long as they don't allocate the same output. Traditional P/PI/PD/PID regulation along with special reflow regulation is supported.

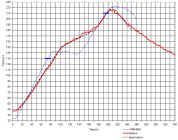

Reflow plate

There are many ways to do reflow soldering and I chose to build a reflow-plate with a 1kW heating element and cooling fan below it. The temperature regulator controls both the heating element and cooling fan so the whole solder process is automatic.

Modification of a solder paste dispenser

I bought a cheap solder paste dispenser from China but unfortunately the timer mode of the dispenser was not good. I decided to modify it by adding a microcontroller based timer between the foot pedal and dispenser unit. This also became the first cirquit board I made from start to finnish with my own tools.

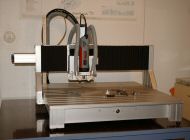

Isel CNC-mill

When making products from start to finnish, there is always mechanical work involved. To aid on this mechanical side, I bough this used Isel CNC-milling machine, which so far has been under constant modifications and improvements. Usable workarea of the machine is 500x480x100 mm (X,Y,Z).